TL:DR – crank but no start, no DTCs, it was the fuel pump.

So, I’ve got a 2006 Infiniti G35 Sedan, with a VQ35DE rev-up engine that randomly died while driving one day. There were no diagnostic trouble codes (DTCs), nothing was obviously broken, belts were intact, no fluid puddles, no strange smells, but I couldn’t get the engine running again so I had it towed to my house.

The only notable information I got out of my OBD scanner was that the battery voltage was too low – under 11V while just sitting there. This led me to believe that the alternator had failed, causing the battery to drain, eventually so much that it couldn’t keep the coil packs firing. Given that there were no codes, no engine stumbling, really no warning at all that something was wrong, this seemed to make sense to me.

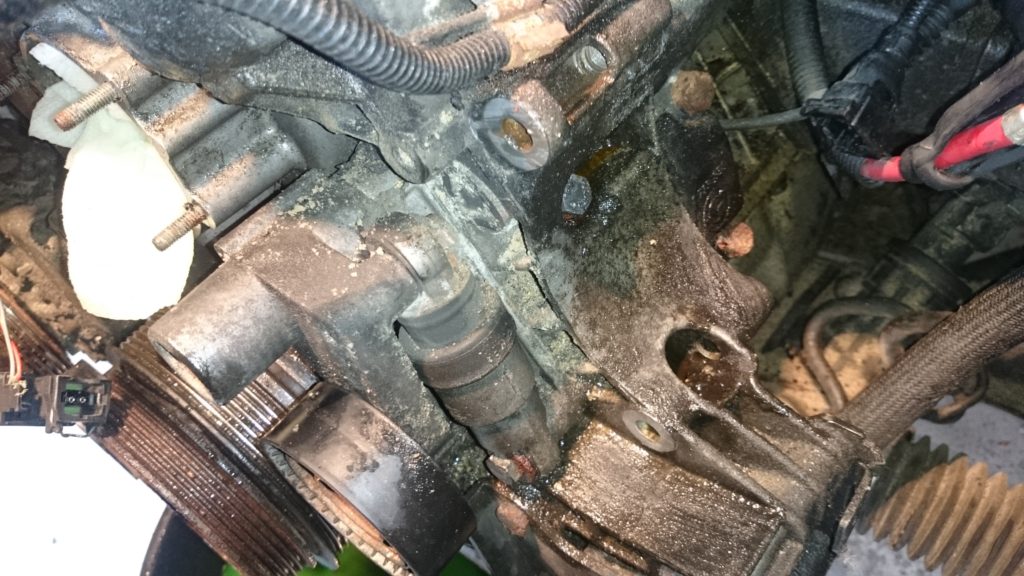

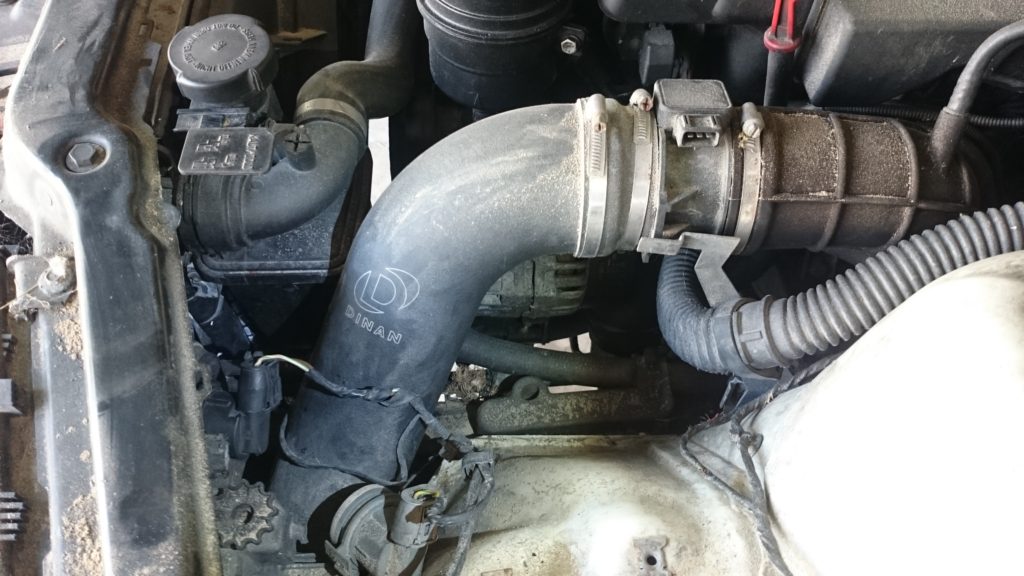

Given my (wrong) diagnosis, I went ahead and replaced the alternator and belts since I had to pull the tensioner out to clear a path for the alternator. The battery was manufactured in 2016, so I replaced that too, just in case. All that, and the engine still wouldn’t start. Still no DTCs. Damn.

Everyone knows you need fuel, air, and spark to run an engine. If I sprayed a little shot of starter fluid into the intake, the engine would run until that burned off. That checked air and spark off the list, and I checked for fuel flow by taking the fuel line off the injector rail and letting fuel flow into a catch can. I tried cranking the engine then checked the catch can, which had fuel in it. OK, so that leaves me with fuel, air, and spark, no DTCs, and an engine that wouldn’t start. Rad. Time to trawl forums.

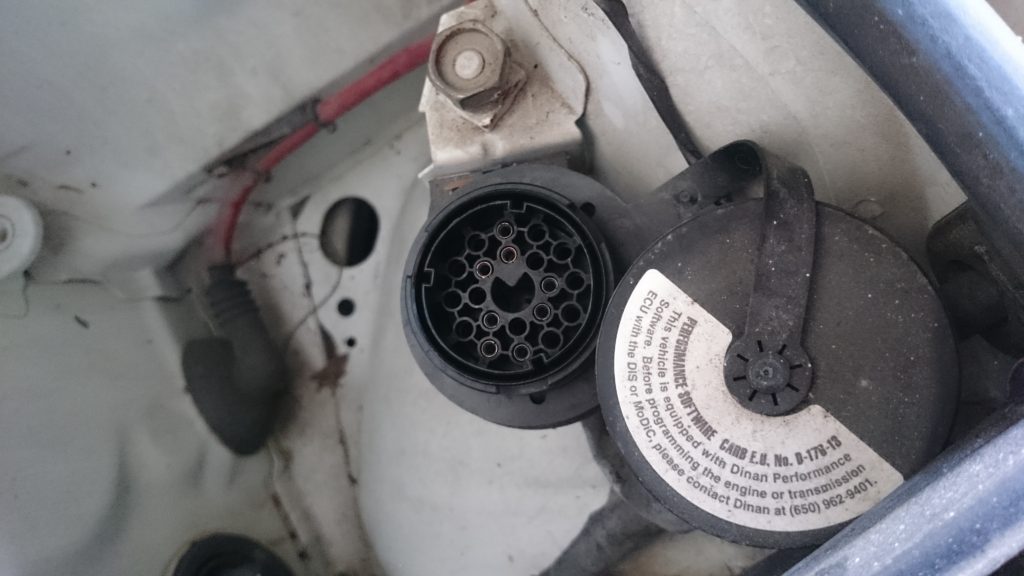

Apparently this behavior is a relatively common occurrence in the G35 and 350Z. Common root causes include bad crankshaft position sensor (prevents spark, not my issue), immobilizer issues due to a bad key (also not my issue, the red security light wasn’t lit), and bad camshaft position sensors (prevent injectors from firing). That sounded a lot like the behavior I was experiencing, but in pretty much every forum post that I saw, they talked about seeing DTCs indicating that these sensors had failed. The ECM was still definitely working because I could see data over the OBD2 link, and disconnecting the above sensors did cause codes to be thrown. Fuck it, sensors are $40 each, and not that terrible to replace, lets just try it. Aaaaand nothing. Same exact behavior.

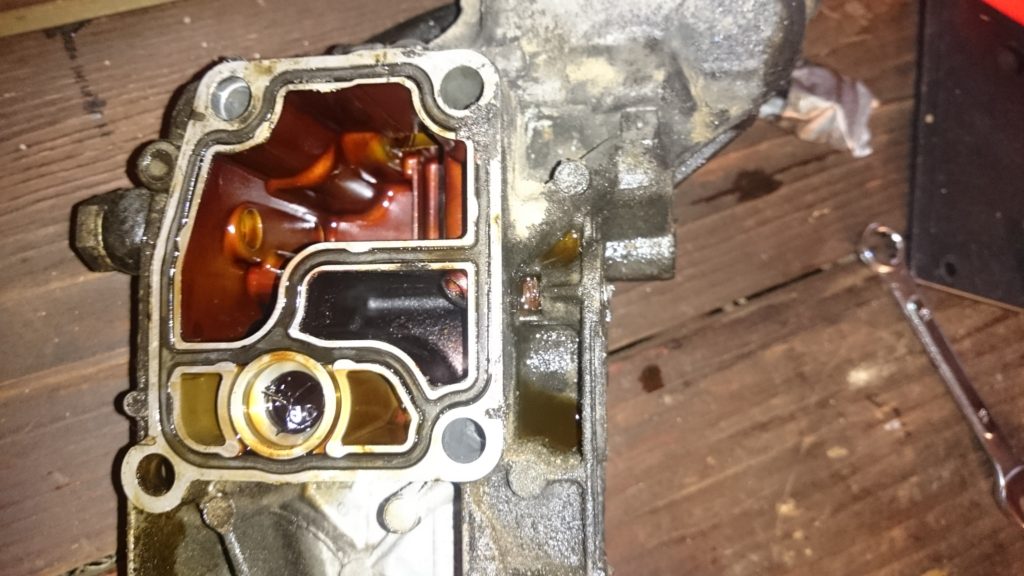

At this point I’m pretty sure its a fuel issue. I pulled the rear seat out, pulled the pump, and checked the filter. I could hear the pump prime when I went to accessory mode, and when I was cranking the engine. Repeatedly cycling the key to prime the fuel system multiple times would get the engine to briefly fire before dying again. I was convinced it was an injector wiring issue at this point.

A friend of mine agreed to come help troubleshoot – an extra set of eyes ears and hands to watch pumps and injectors while the other person is turning the engine over was super helpful. They also brought a fuel pressure gauge; just because I could flow gas into a catch can didn’t mean I had sufficient pressure to feed the engine. We hooked up the pressure gauge, turned the engine over, and saw… 4 psi. Fuel pump it is. We swapped it out for a new one, and the engine fired on the first try.

I’m glad it was something easy, but damn, this really eluded me. I was used to modern high-pressure direct-injection when I worked at Ford, so I was sure a bum pump and low pressure would throw a code. Guess I was wrong!

Since it’s 2021 and forums aren’t really a thing anymore, I decided to write this up for the next poor bastard with a VQ engine that won’t start.