My first major project with the team was during my sophomore year (2012-2013). I was tasked with developing a system to mount the batteries to the car and protect them from a side impact. Luckily, during my freshman year I was given the job of assembling the previous design which involved irregularly shaped aluminum walls and about 1000 pop rivets, so I had a good idea of what not to do. Instead of making a custom enclosure during my sophomore year, I opted to use off-the-shelf parts to make the enclosure easier to build and maintain.

|

|

|

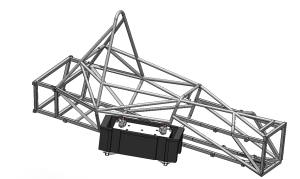

Figure 1: CleanSpeed 1.0 proposed design |

Figure 2: CleanSpeed 1.0 final design |

I used a Stanley tool box as the shell of the enclosure because they are lightweight, waterproof, and inexpensive. I designed a steel skeleton to affix the battery cells to the inside of the enclosure and an exterior cage to protect the battery from a side impact. There were two features of this design that I knew would violate competition rules; the polyethylene box was readily flammable, and the enclosure had conductive penetrations. I fixed these issues before the competition by using an intumescent paint to shield the plastic box and by designing acrylic caps to electrically isolate the inside of the enclosure.