Diagnosing the puddle of coolant started me on a trend of scouring BMW forums for information, how-to’s, and general information about my new project. Luckily (???) coolant leaks are fairly common, and easy to repair on the e46. The major components, thermostat, coolant expansion tank, and water pump, are all plastic, and are prone to cracking as they age. I suspect all of those components were factory originals which a previous owner tried to leak-proof with RTV and silicone caulk instead of repairing. A quick check for dripping coolant confirmed that one of the usual suspects, the water pump, was the leaker. Forum posts recommended replacing the whole cooling system at once to minimize coolant losses, so off I went to the land of aftermarket German car parts to order a new water pump, thermostat, expansion tank, radiator hoses, FEAD (Front Engine Accessory Drive) belt, and miscellaneous O-rings, hardware & sensors.

With many car projects, step 0 is to get it on jack stands and remove the wheels. I have no idea when the last time the wheels came off of this car, but it must’ve been years before I got it. I was attempting to break the lug bolts free with the longest wrench I had; the BMW factory tire iron. It wasn’t long enough that I could just stand on the end of it to break the bolts loose, so I had resorted to stomping on it as hard as I could. This would be the first (but not last) time I’d learn that the right tool makes all the difference; on one bolt I stomped, and my foot slipped between the tire iron and the wheel, very nearly breaking my ankle, and leaving me with a scar on my right ankle. Some time and swearing later, I drove to Harbor Freight and got a 25″ long 1/2″ drive breaker bar.

First up was removing the main fan, draining the coolant loop, and removing the radiator hoses and expansion tank. Up next was removing the AC belt and main FEAD belt. This is where things started going as well as one could expect when working on a car with 210k miles. Both belts had different tensioners, and different methods for releasing the tension to remove the belt. The AC belt needed a 6mm hex (on a socket wrench). In and of itself, that isn’t a problem, the problem was when I knocked the hex adapter off the ratchet and it fell into the gap between the radiator and the front bumper. Knocking on the assembly, you could hear the bit rattling around but I couldn’t see it, I couldn’t reach my hand into the gap far enough to grab it, and I didn’t have the right size cheater pipe to use with a normal 6mm allen key. Seeing that all the hardware stores were closed and I wasn’t ready to stop working, that left removing the bumper and all the electronics in it.

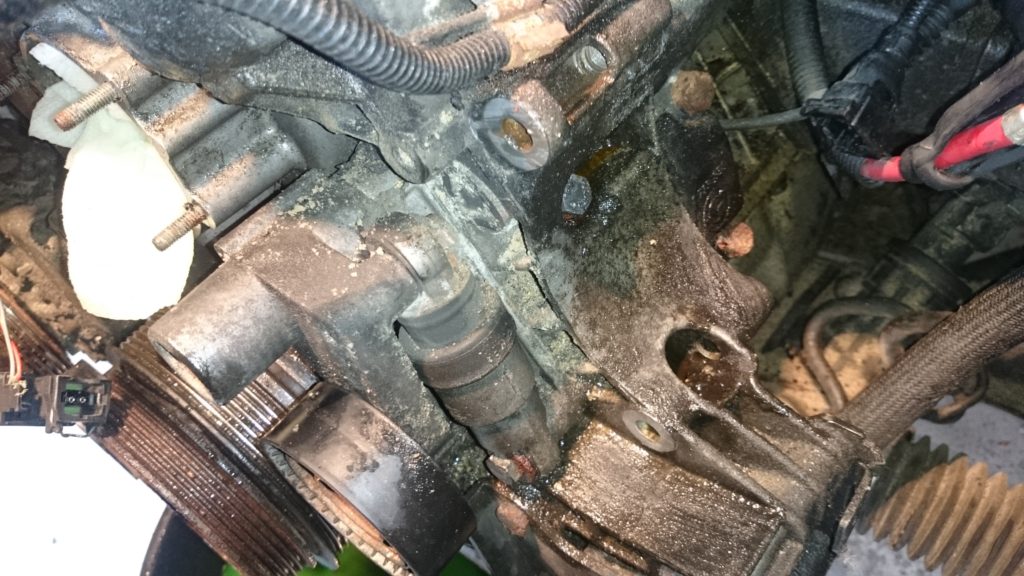

With the recovered adapter, removing the AC belt was as easy as leaning on a socket wrench. The FEAD belt was more challenging since no diagram I found clearly illustrated what bolt you needed to lean on to release tension. I chose one that seemed right, pulled, tired the belt, pulled harder, and then heard a snap. It turns out that I picked the wrong bolt, and snapped my first bolt. This bolt, as far as I knew, was in the engine block and I had put an early end to my project. Before stopping for the day, I continued by removing the thermostat and the water pump, which is where the leak originated at a patched seal.

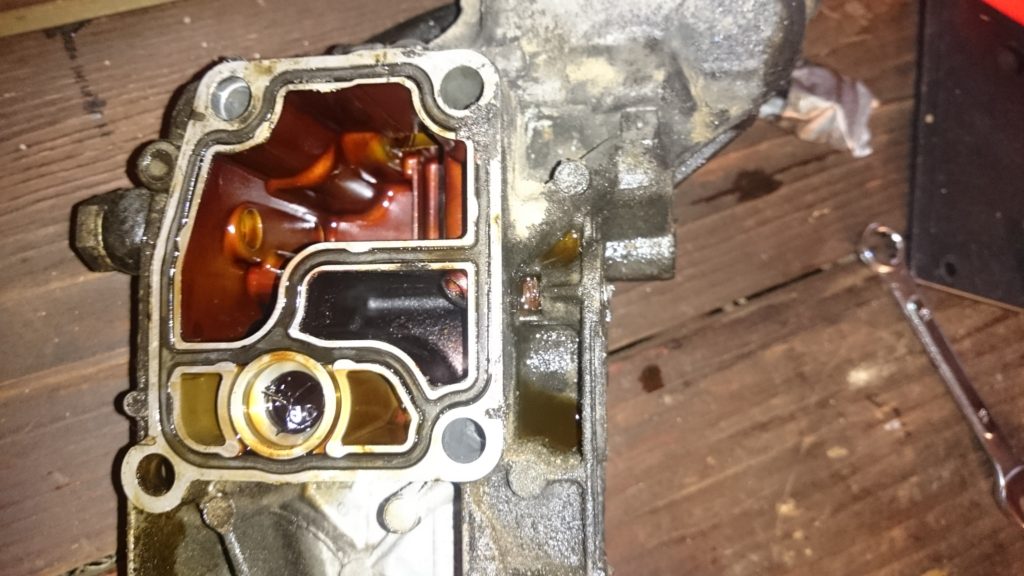

Upon further review, I learned that the broken tensioner bolt was not in the block, but was in the oil filter housing, which was in theory removable. Removing the oil filter housing would also require removing the alternator, and nudging the power steering pump and reservoir out of the way to get access to the six bolts holding it to the block.

A few attempts with an extractor set later, I managed to successfully get the bolt out with no damage to the base metal. I opted to replace the black gasket you can see in the above picture, as it’s a common oil leak spot.

Now the only thing left to remove from the engine before rebuilding the coolant system was the coolant itself. The engine block bleed plug was in a hard-to-reach position, and coupled with whatever corrosion was on the bolt, I couldn’t break it loose, and didn’t want to throw a breaker bar on it for fear of breaking it. Instead, I opted to use an air compressor to blow bursts of air through the block in an effort to clear pooled coolant out of the water jacket with moderate success.