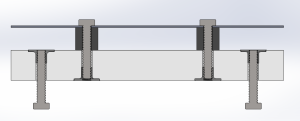

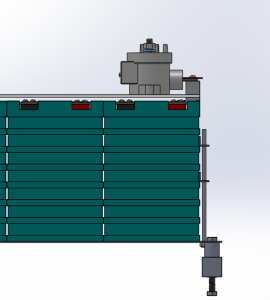

I was elected to the position of Vice President of the team for my junior year (2013-2014). Duties included assisting in managing team resources and being a point of contact with our sponsors in addition to redesigning the battery enclosures. Major changes included a more robust mounting system, improved side impact protection, and better electrical isolation. The batteries were held to a steel plate in the battery box by interfacing with the grooves in their insulation. The steel base plate was held to a plastic bar which was anchored to the bottom of the battery enclosure. The plastic bar had weld nuts embedded in it, which allowed for robust mechanical connections between the batteries and the enclosure, but maintained electrical isolation as is required by the Formula Hybrid Rules.

|

|

|

|

Holding the battery to the box |

Battery packaging |

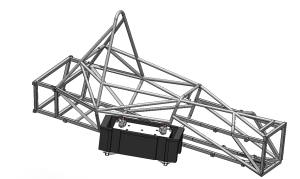

Mounted on car |

Mounting bar cross-section view

In addition to developing the packaging for the batteries, I was in charge of protecting them from a side impact. This involved designing and fabricating a steel cage around the battery boxes on the side of the frame.

We came in 2nd place for the second year in a row, and we were awarded the IEEE award for excellence in electrical vehicle engineering. All that separated us from first place was a single lap on the endurance course, where instead of taking it easy for at least the first lap, I put the pedal to the floor and browned out the battery management system (BMS), putting us out of contention. Oops.